Hydrocarbon Processing was pleased to speak recently with Mark Fonda, Executive Vice President, Engineering and Chief Technical Officer for Meridian Energy Group, which is building two grassroots refineries in the US. The company has announced that these facilities will be among the greenest-operating refineries in the world.

The following Q&A provides an update on the group’s refinery plans, the reason for building the facilities in prolific US shale plays and the technologies the company is utilizing to mitigate emissions and operate as the greenest refineries in the world.

HP: First, tell us about Meridian Energy Group and the two refining projects being built in the Bakken and Permian shale basins.

Fonda: Meridian Energy Group Inc. was formed by a group of North Dakota residents who wanted to create job opportunities in their home state. The company is now building the Davis refinery in North Dakota and plans to build similar facilities in other shale basins throughout the US.

The Davis refinery (Davis) is a 49,500-bpd, full-conversion crude refinery in Billings County, North Dakota—the heart of the Bakken shale basin. Davis will be the:

- First full-conversion, grassroots refinery in the US in more than 40 yr

- Cleanest refinery ever built anywhere in the world, producing the cleanest fuels in the US

- First major refinery built by a development-stage firm

- Model for similar refineries in other shale basins.

Davis has the distinct advantage of being a greenfield, innovative, advanced technology project that will be the most efficient, smartest, ultramodern refinery ever built. It utilizes a distributed business model, and is self-funded and completely independent in its design and operation.

The proven Davis refinery model will serve as Meridian’s winning formula in future shale basin projects. The latest Meridian initiative in the Permian Basin (the Greenfield Project) will incorporate all technological advancements and challenge the current emissions levels within the industry, while maintaining an even larger output than Davis at 60,000 bpd.

HP: What is Meridian’s goal in building two new refineries within these prolific shale plays?

Fonda: Meridian’s goal is to redefine the standards of emissions controls of the refining industry. The physical and operational design of Davis includes implementation of state-of-the-art, lowest achievable emissions rate (LAER) technology, and air pollution control equipment—considered best available control technology (BACT)—to minimize emissions throughout the plant. The design even includes BACT requirements and controls that would be considered maximum achievable control technology (MACT).

HP: Can you provide a status and future scope/timeline of both projects?

Fonda: The 49,500-bpd Davis refinery site construction began in July 2018. Final design and equipment fabrication and procurement is underway, with full construction resuming in 2Q 2019. Meridian plans to have the Davis refinery online in early 2021.

The 60,000-bpd Greenfield Project will likely take less than 1 yr to permit and approximately 2 yr to build and commission. Meridian conservatively estimates about 3 yr to begin full commercial operations, although it could be less. The Meridian plant will not be in operation before the International Maritime Organization (IMO) 2020 deadline for clean fuel requirements, but its fuel oil product will be compliant with those specifications.

HP: Meridian touts that its Greenfield Project will operate as one of the cleanest refineries in the world. How will Meridian accomplish this goal?

Fonda: Meridian will ensure that the required strict air quality standards are met. For example, a comprehensive and enhanced smart LDAR program will be used to monitor fugitive emissions throughout the plant. This innovative solution greatly exceeds the present minimum regulatory requirement, which mandates periodic (e.g., monthly or quarterly) walkthroughs of the facility to monitor each potential source of unintended leakage, utilizing a hand-held screening device, and for repairs to be completed within a specified timeframe. Unintended leaks usually account for a large percentage of hydrocarbon emissions at refineries.

For this reason, and to minimize the potential for unintended leaks at the Davis refinery, Meridian’s LDAR program will utilize optical gas imaging (OGI) technology to continuously scan the equipment. Because fugitive gases are normally invisible to the human eye, OGI cameras use specialized infrared filters that allow them to “see” gas, should it escape. The smart LDAR proposed by Meridian will allow automated early detection and notification of unintended leaks as they occur, and the visual confirmation provided by OGI will be extremely useful in pinpointing the exact source to immediately begin the repair process.

Since 2015, OGI has been identified by the US Environmental Protection Agency (EPA) as the “best system of emissions reduction” for detecting fugitive emissions from new equipment installations, upgrades and modified sources.

HP: Can you explain how both the Davis and Greenfield Project will operate with substantially lower emissions than the industry average on a per-barrel basis?

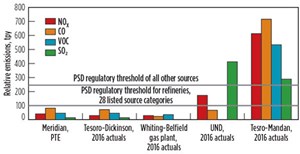

Fonda: The North Dakota Department of Environmental Quality (NDDEQ) review of Meridian’s permit application included most of the requirements reserved to reviews of permit application for major prevention of significant deterioration (PSD) sources of air pollution. Meridian has also provided information in its application that is more typical of a facility applying for a major source permit (e.g., more than 100 tpy of any criteria pollutant). In addition, Meridian’s design has included the implementation of state-of-the-art and BACT to minimize emissions throughout the plant. Davis refinery projected emissions compared to other North Dakota projects are shown in FIG. 1.

In many instances, the company has gone above standard BACT requirements and implemented controls that would be considered MACT. As the agency tasked with protecting the air quality and health of the people of North Dakota, the NDDEQ included specific language in the permit addressing the allowable emissions levels, necessary pollution controls, emissions monitoring, record keeping and reporting far above those for a typical synthetic minor source (SMS) and well beyond the requirements to satisfy North Dakota air pollution control rules and applicable federal regulations.

This has been done to ensure that the facility remains an SMS and to protect the National Park. The Permian (Greenfield Project) facility will also be permitted as an SMS. The Davis refinery is the first full-conversion crude refinery ever to be permitted as an SMS, and Meridian believes that Davis, and now Permian (Greenfield Project), will be the cleanest refineries on the planet when they are operational.

HP: Any additional plans to build more refineries in the other shale plays? Outside of shale plays?

Fonda: Meridian will be looking into building additional units at the Kermit, Texas site for Greenfield Project once the first unit is in operation. Room exists at the Kermit site for up to three additional units, and there is certainly room in the market for the refined products. Meridian is exploring siting options within all other substantial shale basins, and at potentially lucrative logistics chokepoints outside of those basins. The domestic light crude production and transportation network presents Meridian with an exceptionally target-rich environment for siting of small, capital-efficient, cost-effective and environmentally benign, full-conversion oil refineries. HP

Leave A Comment